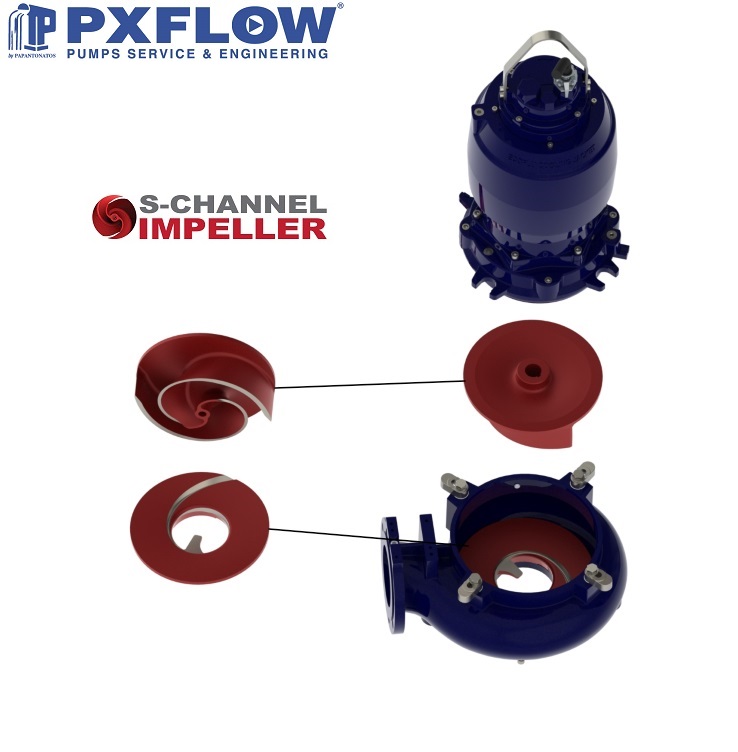

Exciting update from Rhodes Island! The pump stations upgrade project is well underway, with the contractor implementing PXFLOW pumps featuring new wet set installations. These pumps are equipped with guide rails, vortex impellers, and a cooling jacket with an internal close cooling system.

This initiative aims to enhance wastewater management efficiency and establish a sustainable infrastructure. The project guarantees reliable operation even in the most demanding conditions, marking a substantial leap towards modernising wastewater solutions on the island.

Proud to contribute to this crucial project for the long-term sustainability of Rhodes Island!